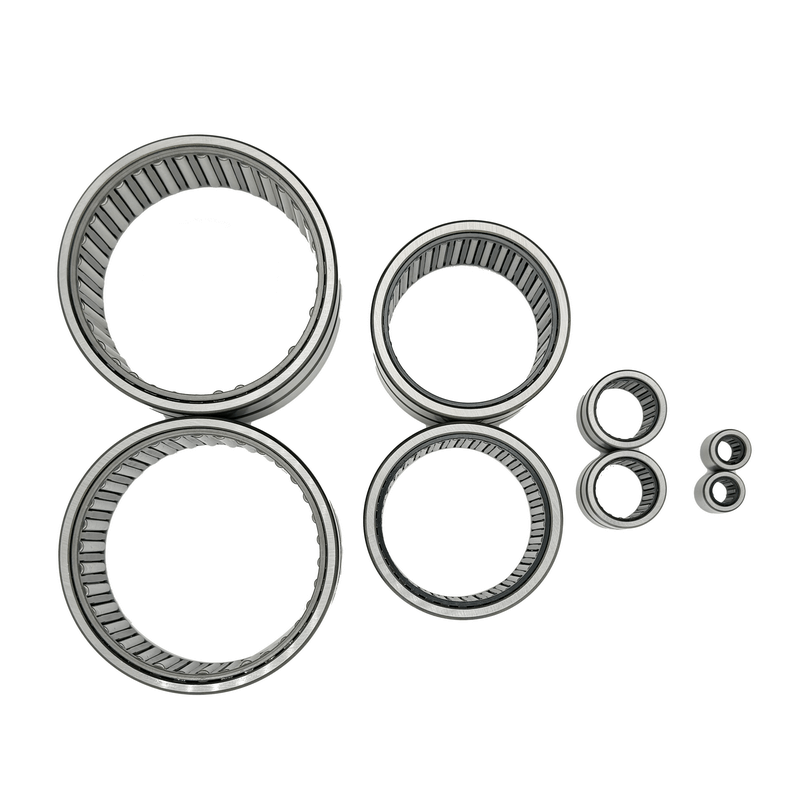

Solid ring needle roller bearings have a compact structure, small radial size, and large load capacity, making them suitable for components with limited radial contour size. They are also widely used in situations where the shaft or shell has swinging motion. Needle roller bearings can generally only withstand radial loads and cannot withstand axial loads. When there is axial load, it should be used in combination with other bearings, which do not limit the axial displacement of the shaft or casing. The limit speed of needle roller bearings is relatively low. When the main engine speed is high, needle roller bearings with cages should be selected as much as possible. Compared with other types of rolling bearings, needle roller bearings have the largest load capacity and higher rigidity, but also larger friction torque, when the radial size is the same

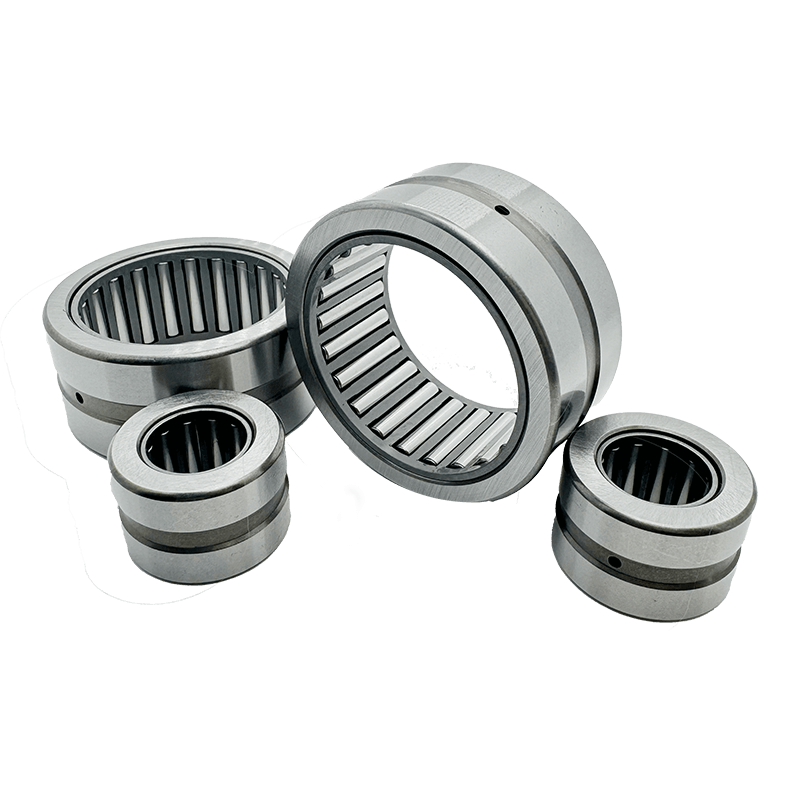

This type of bearing has multiple structures and size series, requiring the surface hardness, machining accuracy, and surface roughness of the journal or shell rolling surface to be the same as the bearing ring. The assembled G2 grade roller needles have a diameter variation of 2 for grouping batches μ Within m, except for fully loaded needle roller bearings, high rigidity cages are used to correctly guide the needle rollers parallel to the axis

Solid ring needle roller bearings include: Non inner ring needle roller bearing RNA. NK typeNeedle roller bearings without inner rings are suitable for components with limited radial dimensions. Due to the absence of inner rings, the surface of the journal that matches them directly serves as the rolling surface. The surface hardness of the bearing is required to be no less than HRC60, and the surface roughness Ra value should not exceed 0.63um. This type of bearing does not limit the axial displacement of the shaft or shell, and its maximum speed is relatively high

Needle roller bearing with inner ring NA NKI type

This type of bearing can be installed separately with the inner ring, outer ring, complete set of rolling needles, and retainer due to the lack of retaining edges on the inner ring, without limiting the axial displacement of the shaft or housing. Due to the use of a cage to separate the needle rollers, friction is reduced, making it suitable for use in components with higher rotational speeds

Personal WeChat

WeCom

Enterprise Tiktok